Evolution of autonomous maritime operations driven by automation technology and digitalisation

BACKGROUND, PREREQUISITE AND FIRST VISIONS OF AUTONOMOUS SHIPS

Radio communication for maritime industry started to develop in the beginning of 1900. 1910-1970 was the period for development of radio communication, gyro compass, radar and heading control. By marine electronics development, 1970-1995 route graphics on radar display, track control, conning displays, GMDSS and GPS and electronic chart systems were developed.

Development of integrated navigation systems started already in 70’s but, it can be said that the navigation system integration really started in the beginning of the 80’s by available electronic devices and systems, followed by speed control and AIS-systems in late 80’s. Study of “Ship of the Future” started in 1980.

Meanwhile navigation and communication systems got more automated, control and functions of machinery systems started to be based on automation as well, thanks to better sensor technology and computers. Today, in modern vessels, almost everything is controlled via ship’s automation system (IAMCS) with protective functions for the equipment. The system might take care of thousands of I/O channels. That alloys automated HVAC systems, diesel electric propulsion and power plant with Power Management System (PMS) etc. Everything is mostly automated which the ship’s crew controls and makes corrective actions and orders.

Vision of autonomous ships published already before ship systems started to get automated. As early as 1970´s, vision of autonomous ships was launched by Rolf Schonknecht in his book “Ships and Shipping of Tomorrow”.

PROGRESS OF AUTONOMOUS MARITIME OPERATIONS DEVELOPMENT

There are several names and definitions for different types of automated ships with different level of autonomy; remotely controlled, unmanned, autonomous etc. IMO has also defined different levels for Maritime Unmanned Surface Ships (MASS). Unmanned ship can be remotely controlled or autonomous, but autonomous ship must be able to operate without human assistance, though it is monitored by crew onboard or shore based Shore Control Center (SCC). As nowadays, most of the ship systems are highly automated, there is still a lot of work to create such a complete and absolute wholeness with algorithms, artificial Intelligent and machine learning, to fulfill all functions and circumstances which might occur in maritime operations. Maritime environment is much more complicated and variable than the road network onshore. The responsibility matter, if something unexpected happens, is not adequately solved yet.

Japan had a project in 1982-1988 to develop a highly reliable, intelligent and automated operational systems in maritime operations, remotely controlled from shore based control station. Korea started to research an Unmanned Autonomous Surface Vessels for maritime survey and surveillance in 2011. European MUNIN project 2012, REVOLT by DNV-GL 2013-2018, AAWA project led by Rolls-Royce 2015, Lloyd’s Register Guidance 2016, MOL project for Autonomous Ocean Transport System 2017, just to mention few projects. The World’s first Autonomous Shipping Company Masterly established in 2018 by Kongsberg and Wilhelmsen.

Picture 1: One Sea Autonomous Maritime Ecosystem

2019-2020 some full scale (tug boat and archipelago ferry) tests of remotely operated and autonomous vessels have been performed. Thus some companies have had plausible and illustrative demos about autonomous vessels for high seas, eagerness has settled down towards short voyages close to the coast, rivers and city areas. For long term, environmental friendliness and ecological efficiency, might cause restrictions for propulsion power and speed, which might support the struggle towards autonomous and unmanned shipping.

Technology companies and developers have been worried about slow reaction of authorities to get this issue forward, to achieve regulations for autonomous shipping operations. But as seen, local authorities gave permit to test autonomous operations in certain pointed areas. They don’t want to prevent the development progress, but technology drives the way. Around 2015-2020 hype of autonomous ships pushed IMO to concentrate on legislation for autonomous vessels more deeply. Regarding regulation, IMO takes first step to address autonomous ships and defines Maritime Autonomous Surface Ship (MASS) in 2018, DNV GL released guidelines for Autonomous and Remotely Operated ships. Now at IMO, there is an evaluation projects for needs and content of regulation for autonomous ships and operations according to their strategic plan 2018-2023.

AUTOMATION TECHNOLOGY OF SHIP SYSTEMS LEAD THE WAY OF AUTONOMOUS MARITIME OPERATIONS

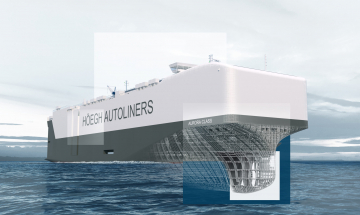

Ship system providers develop automation in their own product portfolio and that is probably strongest accelerator in contest of achieving autonomous systems and fighting against challenges in this complicated operating environment. Few years ago, hype of autonomous ships and digital transformation spread in many countries, not least in European countries. There have been several research and development projects, tests and real projects to build autonomous ships as well. Nevertheless, it seem not to be as easy. Well known project “Yara Birkeland”, 120 TEU container vessel, is one example of the complexity of this kind of vessel and operation. Even it is meant to sail only short voyages in restricted area at coast of Norway, the wholeness is still complex. The project is still alive and most probably to be succeeded, but to be postponed. Initial goal was to start operation in 2019 and to be fully autonomous in 2020. The latest published schedule is to be in test run period during 2020, in operation 2021 and fully autonomous in 2022. The hull is already on the way to delivery shipyard for outfitting. The Yara Birkeland is aimed to be zero emission vessel, and also loading and unloading is planned to be autonomous.

Picture 2: Yara Birkeland

MacGregor responded to their customer request to develop an autonomous crane for ESL-Shipping. The autonomous discharging crane system for bulk cargo operates driverless, controlled from the command bridge. That is one impressive example how the wholeness is knitting together by individual equipment and systems, one by one.

Today, there are such a wide range of automated and autonomous systems available, that major players have good opportunities to integrate and deliver all the needed systems for fully autonomous vessels intended for short voyages in restricted areas. Vessels to be more integrated and connected by digitalization, they come more autonomous regardless they have crew on board or not. Lot of effort has been made to develop algorithms and AI. For example, ABB, Wärtsilä and Kongsberg with partners have all the opportunities to achieve this goal in the near future. It is stated in many sources, that autonomous vessels will sail within next few decades. Nevertheless, it will grow up step by step, according to the development of individual system provides. Next steps to be, is to have autonomous systems which supports the crew in their actions and decision making. But in the beginning, crew onboard or at control stations ashore, utilizes the support of autonomous systems and still have the control of the ship. Autonomous shipping and autonomous maritime operations doesn’t only mean the autonomous ship. Fairways and harbor areas have to integrate to wholeness of autonomous operations too, including piloting and VTS control, berthing and cargo operations.

Regardless of the operational format, autonomous, remotely operated/controlled or traditionally operated by crew of the ship, the vessel need to be engineered any way. Elomatic Consulting and Engineering Ltd is looking forward to be a partner for ship owners and shipyards in ship design engineering processes in all phases, meeting future needs.

Elomatic has competitive teams for hull design, outfitting and machinery engineering, and for electricity, automation and interior design as well. Elomatic has also a strong team for visualization and simulation. Personnel of Elomatic consist of versatile experience with strong knowledge of design engineering and project management, and operational experience as well, like deck officers, master mariner (Captain) and maritime engineers with long sailing career.

Author

Kimmo Matikka

Project Manager, Marine & Offshore

Originally published by Elomatic Oy

Yara Birkeland images: Copyright © 2004 - 2021 Yara International ASA